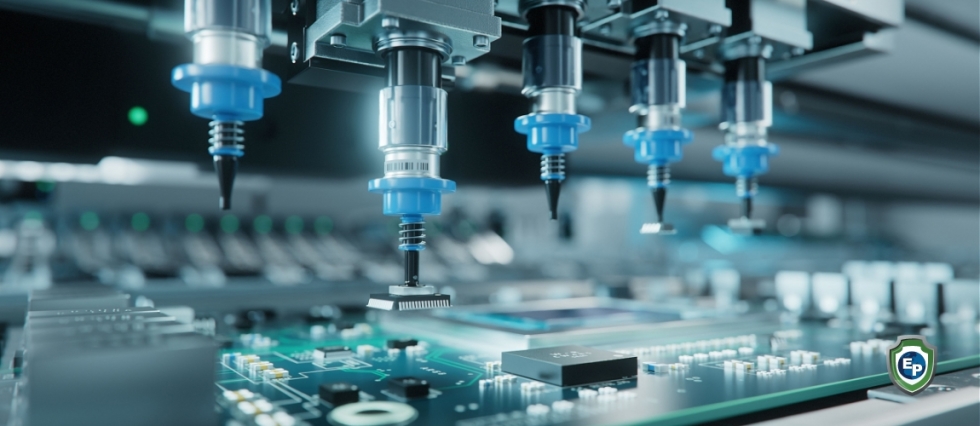

Manufacturing Technology Trends that will Transform Lives

Manufacturing Technology Trends will transform lives and the world around us. This article explores the current trends in manufacturing and what they mean for our future.

The evolution of technology has brought about tremendous improvements and growth in the manufacturing sector that can transform lives. Besides the physical facets of manufacturing, there are advancements in digitization that enable industrial manufacturers to develop smart collaborations, new operational models, directed investments, and aggressive hiring. The current new manufacturing processes can renew the waning U.S. manufacturing. Here are some of the trends in the manufacturing industry that stakeholders must beware of.

Employee Safety is Still Paramount

While many manufacturers have always prioritized employee safety, things changed significantly during the pandemic. Apart from standard precautions like sanitizing the work area and maintaining social distance, manufacturers must monitor who accesses or exits their facilities today. They should also watch individuals on the work floor and the equipment they work with.

Many manufacturers are now in-sourcing facility management and maintenance to facilitate employee safety, emphasizing traceability. This requires them to recoup internal equipment data from original equipment manufacturers (OEMs). This enhanced focus on worker safety surpasses field service to reduce contact.

Technicians will have to be better prepared for every job to facilitate faster completion of orders which may lead to a rise in manufacturer FTFR (first-time fix rates). This trend will likely affect supply chain visibility directly as manufacturers seek more transparency from suppliers to track claims and issues across the manufacturing process.

IoT Remains the Big Thing

While IoT is fast becoming a standard technology in the manufacturing sector, it remains a top trend for its innovation and adaptability. IoT involves the interrelationship of exclusive devices in an existing internet framework. This technology allows manufacturers to make strategic and informed decisions using real-time data. They can also achieve various goals like enhanced efficiency, cost reduction, product innovation, and safety. According to a study by the MPI Group, almost 31% of production procedures now include embedded intelligence and smart devices.

Further, 32% of manufacturers are preparing to embed IoT into their products, while 34% want to integrate IoT into their processes. In a recently concluded webinar, Hitachi Solutions America’s Vice President of Advisory Services, Jim MacLennan, said:

There are three fundamental components of business that information has changed: internal operations, how you connect with your customers, and now, information has become a new and differentiating feature for your products. So you can compete and win, grow markets, and take share. It’s a fundamental change to the nature of products.”

IoT-oriented devices allow manufacturers to monitor equipment performance safely and identify potential problems before a breakdown occurs. They also enable technicians to understand a problem and devise possible solutions off-site. That way, they can accelerate the resolution process.

Other trends in the manufacturing industry to watch out for include:

● Predictive maintenance

● Re-evaluation of sourcing and shoring

● The transition from B2B to B2C

● 3D printing

● A new approach to enterprise resource planning (ERP)

Will Manufacturers Adopt New Technologies?

Technology will continue evolving. As a result, manufacturers with outmoded processes and techniques must consider upgrading their equipment and digital framework. They should also hire emerging talent combining digital and manufacturing skills to set the stage for collaborations with organizations with more advanced digital resources.

Stay Tuned with Export Portal

For information on how B2B export works, be sure to check out our Blog Page today!

Comments 0